Functional Polymers Engineering

Scientific objectives

- Development of new photoinitiating systems

- Development of processes and innovative techniques in photopolymerization

- Development of new synthetic methodologies combining photopolymerizations and controlled radical polymerizations

- Control of growth, chemistry and morphogenesis of thin films fabricated by plasma-assisted polymerization

- Design of surfaces and interfaces with controlled chemical and physico-chemical properties, towards fabrication of stimuli-responsive surfaces

Members

Aissam AIROUDJ

Engineer

➜ CV

Florence BALLY-LE GALL

Assistant professor

Co-leader

➜ CV

Jean-Michel BECHT

Assistant professor

➜ CV

Abraham CHEMTOB

Assistant professor

➜ CV

Céline DIETLIN

Assistant professor

➜ CV

Claude LE DRIAN

Professor

➜ CV

Bernadette GRAFF

Engineer

➜ CV

Dimitri IVANOV

➜ CV

Philippe KUNEMANN

Assistant engineer

➜ CV

Jacques LALEVEE

Professor

➜ CV

Fabrice MORLET-SAVARY

Research scientist

Co-leader

➜ CV

Vincent ROUCOULES

Professor

IS2M director

➜ CV

Research fields

Design of new photoinitiating systems as well as photosensitive resins for specific applications.

J.M.Becht, C. Dietlin, B. Graff, J. Lalevée*, F. Morlet-Savary

*Contact : jacques.lalevee@uha.fr

The development of photosensitive resins for radical or cationic polymerizations or of the preparation of interpenetrated polymer networks require high-level, fundamental investigation of both the photoinitiating systems (e.g. under mild conditions of light irradiation) and each component of the photosensitive resin (e.g. new monomers, hybrid polymerization, stabilizers…).

In fact, it is through a complete optimisation of the photosensitive resin (i.e. photoinitiating system with monomers and other additives) that the final properties of the material created through light irradiation are then enhanced for its use in several fields such as dental materials, surgical glues, functional coatings, building and industrial materials.

The most significant point relies upon the fundamental knowledge of the chemical processes governing the reactivity of these photosensitive resins.

Publications :

Silyl Glyoxylates as a New Class of High Performance Photoinitiators:Blue LED Induced Polymerization of Methacrylates in Thin and Thick Films

M. Bouzrati-Zerelli, J. Kirschner, C. P. Fik, M. Maier, C. Dietlin, F.Morlet-Savary, J. P. Fouassier, J.-M. Becht, J. E. Klee and J. Lalevée

Macromolecules 50(17), 6911-6923 (2017) DOI : 10.1021/acs.macromol.7b01370

NIR Organic Dyes as Innovative Tools for Reprocessing/Recycling of Plastics : Benefits of the Photothermal Activation in the Near-Infrared Range

V. Launay, A. Caron, G. Noirbent, D. Gigmes, F. Dumur and J. Lalevée

Advanced Functional Materials 31(7), 2006324 (2021) DOI : 10.1002/adfm.202006324

Bis-chalcone derivatives derived from natural products as near-UV/visible light sensitive photoinitiators for 3D/4D printing

H. Chen, G. Noirbent, S. Liu, D. Brunel, B. Graff, D. Gigmes, Y. Zhang, K. Sun, F. Morlet-Savary, P. Xiao, F. Dumur and J. Lalevée

Materials Chemistry Frontiers 5(2), 901-916 (2021) DOI : 10.1039/D0QM00755B

New multifunctional benzophenone-based photoinitiators with high migration stability and their applications in 3D printing

S. Liu, D. Brunel, G. Noirbent, A. Mau, H. Chen, F. Morlet-Savary, B.Graff, D. Gigmes, P. Xiao, F. Dumur and J. Lalevée

Materials Chemistry Frontiers 5(4), 1982-1994 (2021) DOI : 10.1039/D0QM00885K

Radical photoinitiation with LEDs and applications in the 3D printing of composites

Y. Zhang, Y. Xu, A. Simon-Masseron and J. Lalevée

Chemical Society Reviews 50(6), 3824-3841 (2021) DOI : 10.1039/D0CS01411G

Photoinitiators : Structures, Reactivity and Applications in Polymerization, Book, Issue (2021)

J. P. Fouassier and J. Lalevée

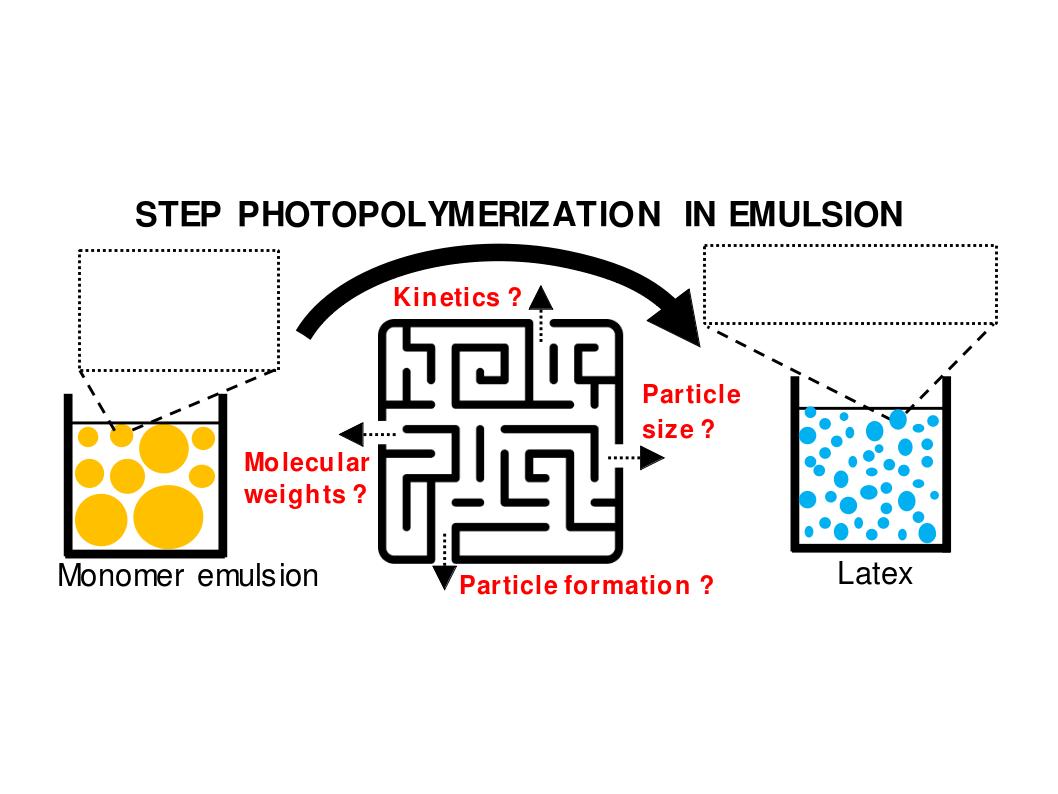

Photopolymerization in dispersed systems

A. Chemtob*

*Contact : abraham.chemtob@uha.fr

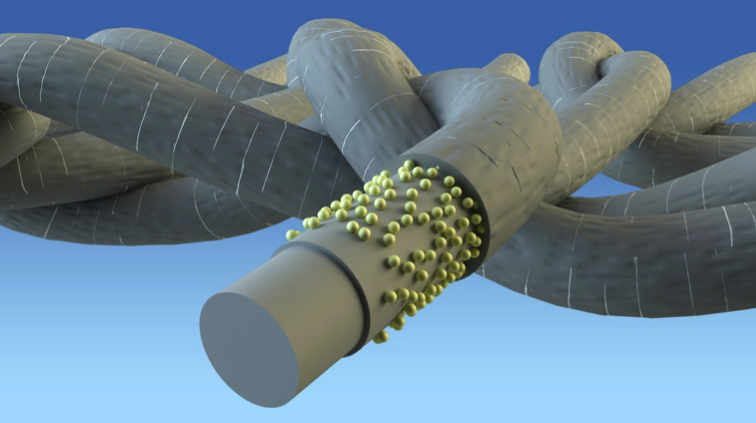

The polymer industry is going through one of the most significant periods of change in its history. Driven by new environmental regulations, the development of eco-efficient processes and zero-VOC products has become an absolute necessity. In this field, 2 technologies stand out : Polymerization in dispersed media and Photopolymerization. By combining these two main processes, we aim to develop a “hybrid” next-generation technology based on thiol-ene photopolymerization in dispersed media. Advanced manufacturing based on photoreactor promises a wave of high sulphur content dispersed products (films, nanoparticles, porous network). Their outstanding properties open the door to applications responding to current industrial needs such as non-leaching materials, O2 barrier and biobased waterborne coatings, biologically-active particles, hybrid nanosensors and monolithic chromatography column.

Funding :

PHOTO-EMULSION is a EU-funded Innovative Training Network (ITN) project of the H2020 programme. Led by IS2M (Dr. Abraham Chemtob), it involves a high-quality research network including 8 internationally reputed academic institutions, 4 leading companies and 2 non-profit organizations. Balanced & EU-wide, its diversity expresses through the participation of 8 countries (Austria, France, Germany, Ireland, Poland, Slovenia, Sweden & Spain), 50 % female scientists-in-charge, and structures supporting gender equality.

Publications :

Ab Initio Batch Emulsion Thiol–Ene Photopolymerization, Cuong Minh Quoc Le, Marc Schmutz, and Abraham Chemtob, Macromolecules 2020, 53, 2369-2379. DOI : 10.1021/acs.macromol.0c00265

Feature article Advances in Engineering

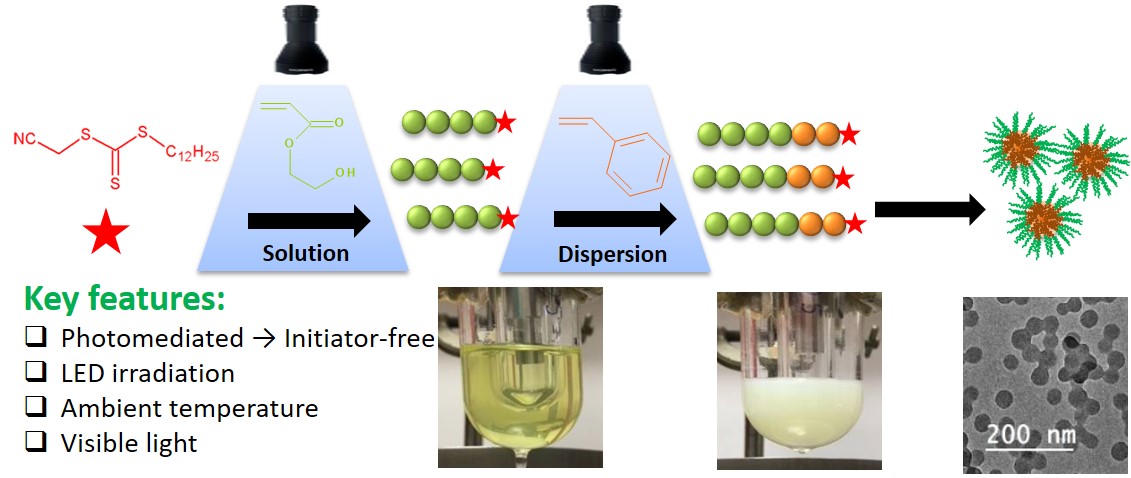

Photo-induced macromolecular engineering

A.Chemtob

*Contact : abraham.chemtob@uha.fr

The introduction of external stimuli in synthetic methodologies has become a very active research axis in the field of macromolecular engineering. In this context, we are developing photo-mediated controlled radical polymerization mechanisms using LEDs as light sources emitting in the visible domain. We have focused on photopolymerization-induced self-assembly (photoPISA) based on photomediated RAFT polymerization mechanism, which has emerged as a major method for the visible light-driven synthesis of amphiphilic block copolymer nanoparticles. Photochemically initiated PISA opens avenues for improved process conditions in regards to reaction efficiency, energy consumption and safety. the potential of PISA-derived nano-objects in two emerging fields : templated synthesis of mesoporous carbon materials and optical imaging of cells using fluorescent nanoparticles.

Publications :

Tkachenko, V. ; Vidal, L. ; Josien, L ; Schmutz, M. ; Poly, J. ; Chemtob, A. Characterizing the Core-Shell Architecture of Block Copolymer Nanoparticles with Electron Microscopy : A Multi-Technique Approach. Polymers 2020, 12, 1656. DOI : 10.3390/polym12081656

Tkachenko, V. ; Josien, L. ; Schrodj, G. ; Hajjar-Garreau, S. ; Urbaniak, S. ; Poly, J. ; Chemtob, A. A DSC and XPS characterization of core–shell morphology of block copolymer nanoparticles. Colloid Polymer Science 2020, 298, 1095. DOI : 10.1007/s00396-020-04676-7

Tkachenko, V. ; Matei Ghimbeu, C. ; Vaulot, C. ; Josien, L. ; Vidal, L. ; Poly, J. ; Chemtob, A. Diblock Copolymer Core–Shell Nanoparticles as Template for Mesoporous Carbons : Independent Tuning of Pore Size and Pore Wall Thickness. Langmuir 2019, 35, 16324. 10.1021/acs.langmuir.9b02994

Tkachenko, V. ; Ghimbeu, C. M. ; Vaulot, C. ; Vidal, L. ; Poly, J. ; Chemtob, A. RAFT-Photomediated PISA in Dispersion : Mechanism, Optical Properties and Application in Templated Synthesis. Polym. Chem. 2019, 10, 2316. 10.1039/C9PY00209J

Plasma-assisted polymerizations

A. Airoudj, F. Bally-Le Gall, P.Kunemann, V. Roucoules*

*Contact : vincent.roucoules@uha.fr

A plasma produces a wide range of species (molecules, atoms, radicals) in many energetic states (ionized, excited, metastable and fundamental states). These precursors can react or self-assemble to form solid polymeric objects with specific properties. Our aim is to understand and control the mechanisms related to the morphogenesis of complex structures induced during plasma polymerization. The challenge comes from the difficulty in identifying the predominant species leading to the formation of organised units and from multi-scale dimensions of these systems for which chemical and physical phenomena can occur at different spatial and temporal scales.

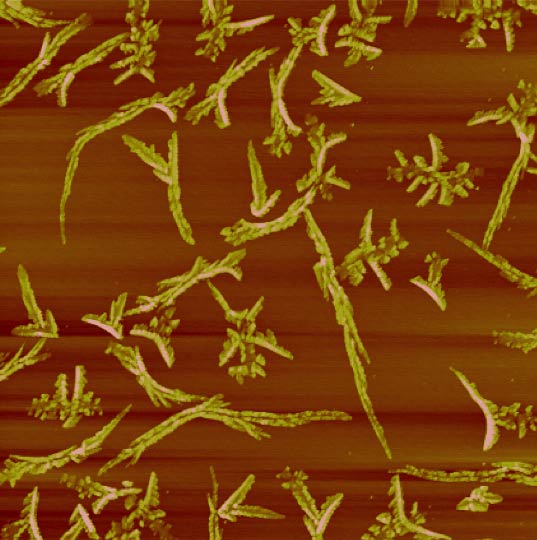

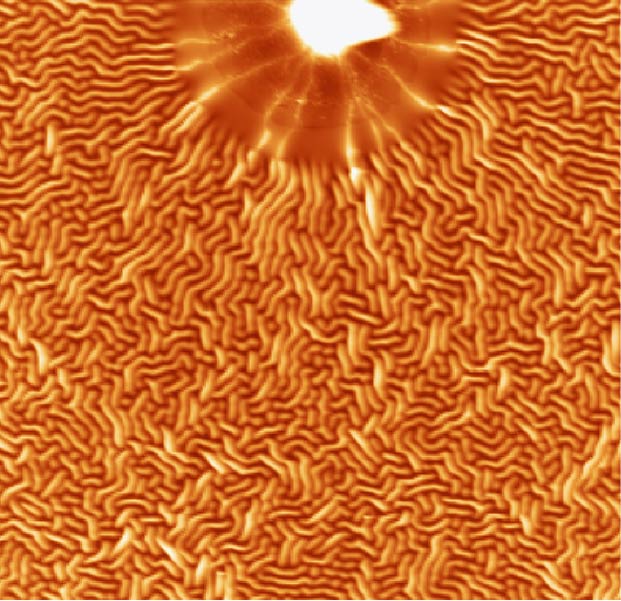

Reprinted with permission from Brioude, M. M., Laborie, M.-P., Airoudj, A., Haidara, H. and Roucoules, V. (2014), Controlling the Morphogenesis of Needle-Like and Multibranched Structures in Maleic Anhydride Plasma Polymer Thin Films. Plasma Process. Polym., 11 : 943–951. doi:10.1002/ppap.201400057.

Reprinted with permission from P. Samyn, M.-P. Laborie, A. P. Mathew, A. Airoudj, H. Haidara, and V. Roucoules, Metastable Patterning of Plasma Nanocomposite Films by Incorporating Cellulose Nanowhiskers, Langmuir 2012 28 (2), 1427-1438, DOI : 10.1021/la202503h. Copyright 2012 American Chemical Society.

Publications :

Brioude, M.D., Laborie, M.P., Airoudj, A., Haidara, H. and Roucoules, V., Plasma processes and polymers 2014, 11, 943 DOI : 10.1002/ppap.201400057

Brioude, M.M., Laborie, M.P., Haidara, H. and Roucoules, V., Plasma Processes and Polymers 2015, 12, 1220 DOI : 10.1002/ppap.201400224

Brioude, M.M., Roucoules, V., Haidara, H., Vonna, L. and Laborie, M.-P., ACS Appl. Mater. Interfaces 2015, 7, 14079. DOI : 10.1021/acsami.5b03302

Fabrication of smart interfaces

A. Airoudj, K. Anselme, F. Bally-Le Gall*, T. Petithory, V. Roucoules

*Contact : florence.bally-le-gall@uha.fr

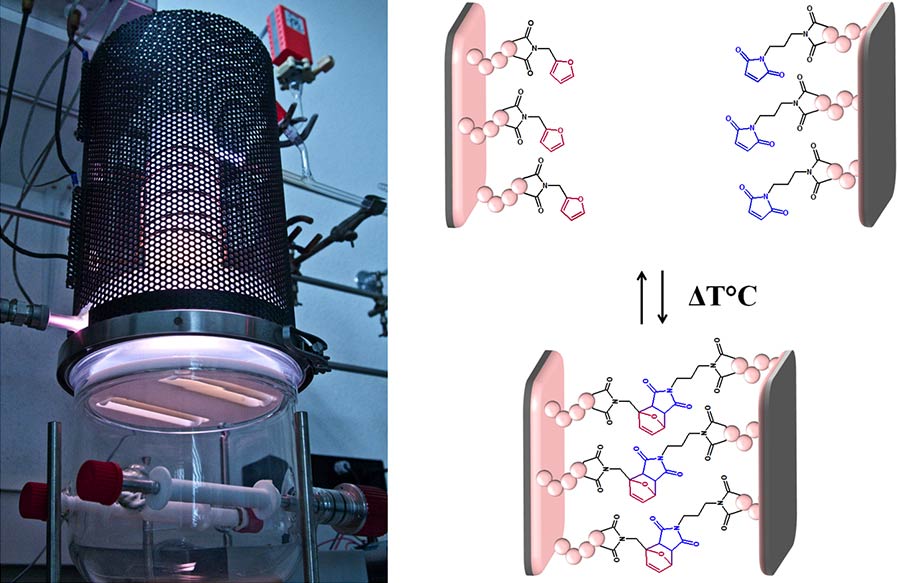

The fabrication of functional coatings responding to a (thermal or mechanical) stimulus provides smart properties to the surface of the material. Therefore, the interactions of the latter with its environment can be controlled without changing its formulation. The design of such smart interfaces can be assisted by plasma polymerization and post-modification of functional polymer coatings. For instance, the control of interfacial reactivity has enabled the production of reversible covalent adhesion between two substrates. A simple temperature change enables to assemble or disassemble materials via a plasma polymer functionalized with Diels-Alder reactive groups.

Publications :

ANR JCJC INTHERMO (smart INterfaces with THERMO-reversible properties) 2016-2019

Projet Idex avec l’Université de Strasbourg (collaboration avec Pr. Pierre Schaaf) 2015-2017

Bacharouche, J., Badique, F., Fahs, A., Spanedda, M.V., Geissler, A., Malval, J.-P., Vallat, M.-F., Anselme, K., Francius, G., Frisch, B., Hemmerlé, J., Schaaf, P. and Roucoules, V. ACS Nano 2013, 7, 3457 DOI : 10.1021/nn400356p

Design of antibacterial surfaces

A. Airoudj, P. Kunemann, V. Roucoules

*Contact : florence.bally-le-gall@uha.fr

Our research activities for the development of new antibacterial surfaces rely on both preventive and bactericidal approaches. We aim to achieve high performances in terms of durability of the properties (resistance to ageing, long-term delivery of an active substance) and health and environmental risks (control of the nano-objects, of the delivered doses). What makes our materials and coatings unique is that we favour new antibacterial preventive strategies (e.g. specific mechanical properties) and bactericidal, stimuli-responsive strategies to avoid or restrict delivery of antibacterial but toxic molecules to necessary doses. Both approaches can also be coupled for improved antibacterial performances.

Publications :

N. Cottenye, K. Anselme, L. Ploux, C. Vebert‐Nardin, Adv. Funct. Mater., 22 : 4891–4898 (2012) DOI :10.1002/adfm.201200988

E. Kulaga, L. Ploux, L. Balan, G. Schrodj, V. Roucoules, Plasma Process. Polym. Vol. 11, pp. 63-79 (2014) DOI :10.1002/ppap.201300091

E. Kulaga, L. Ploux, V. Roucoules, Polymer Degradation and Stability Vol. 116(0), pp. 1-13 (2015) DOI :10.1016/j.polymdegradstab.2015.02.011

Specific facilities

Plasma reactors

(low pressure and atmospheric pressure)

Irradiation sources(UV, LED…)

3D printer

UV-visible absorption spectrophotometers

Fluorimeter

Setup for laser flash photolysis (LFP)

Spectrometer for electron paramagnetic resonance (EPR)

FT-IR spectrometers

Size exclusion chromatographs

Equipments for microbiological culture

Automatic applicator bar coaters and flexo

Irradiation bench

C.V.D.

Spincoater

Leica JungLN20 Microtome

Optical emission spectrometer

Horizontal low pressure plasma reactor

Horizontal low pressure plasma reactor

Rotative low pressure plasma reactor

Atmospheric pressure plasma reactor

Low pressure plasma reactor for surface activation

Main collaborators

Institut Charles Sadron (Strasbourg, France)

Institut Jean-Lamour (Nancy, France)

Institut de Chimie Radicalaire (Marseille, France)

University of Pittsburgh (Etats-Unis)

Albert-Ludwigs-Universität Freiburg (Allemagne)

Luxembourg Institute of Science and Technology (Luxembourg)

Huaiyin Institute of Technology (Chine)

Quantapplic CEO (Germany)

Carmegie Mellon University (Etats-Unis)