Light-induced additive manufacturing

Light-induced additive manufacturing

Arnaud Spangengerg arnaud.spangenberg@uha.fr

Light-induced additive manufacturing

The hierarchical structuring of matter in natural systems is incredibly complex and fascinating in many ways. The interplay between (bio-)chemical reactions and physical phenomena can give rise to an almost infinite collection of patterns and shapes, with inert or evolving properties depending on the environment. To reproduce such beautiful organization, the aim of our research group is to carry out innovative research in all modern areas of light-based additive manufacturing, including fundamental and applied research as well as industrial innovations.

Harnessing the basic principles that guide light-matter interactions is therefore of fundamental scientific interest, but also promises a paradigm shift in the manufacturing of advanced functional materials.

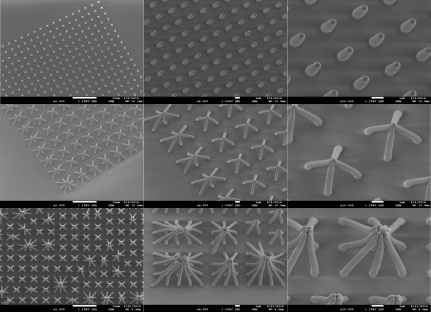

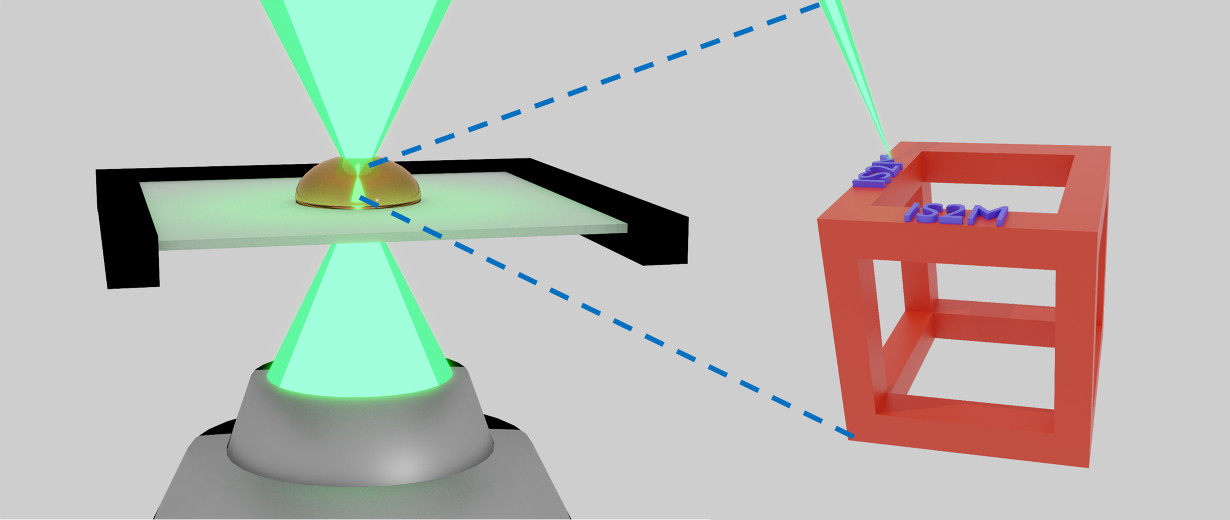

New original strategies for light-induced macro- to nano-fabrication and dedicated materials have been developed. Some recent examples include 2-photon stereolithography, capillarity force assisted 3D direct laser writing, Multi-scale 4D printing, tomographic volumetric additive manufacturing… Current research includes the development of new routes to control the 3D assembly of various molecular building block and to provide an adaptive and programmable behavior to the resulting hierarchical architectures (Tunability of the shape, function, crystallinity, optical properties…).

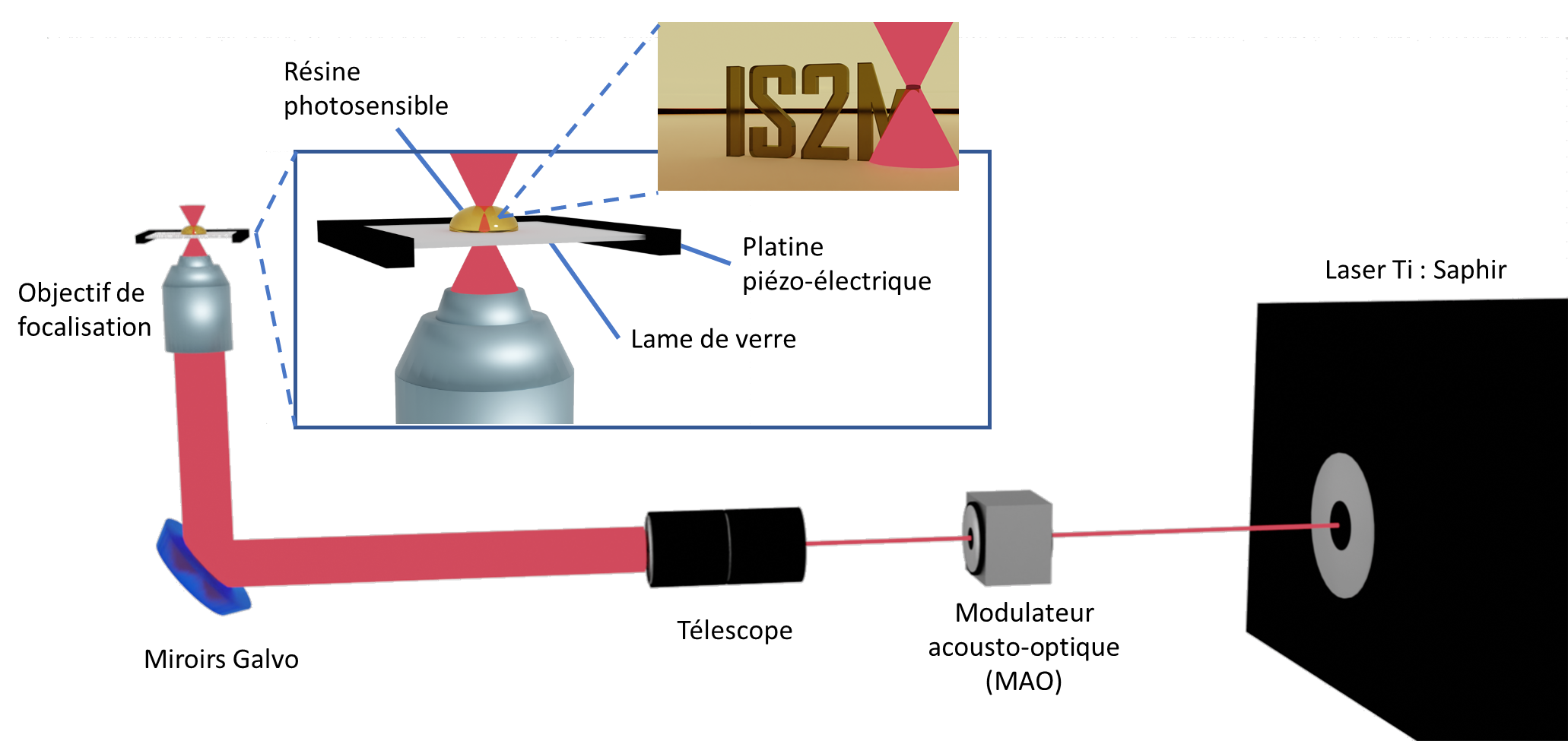

Multi-wavelength 3D direct laser writing (3D DLW) set-up

Pillar assembly made by Capillarity force assisted 3D DLW

NanoPhotochemistry and Microspectroscopies

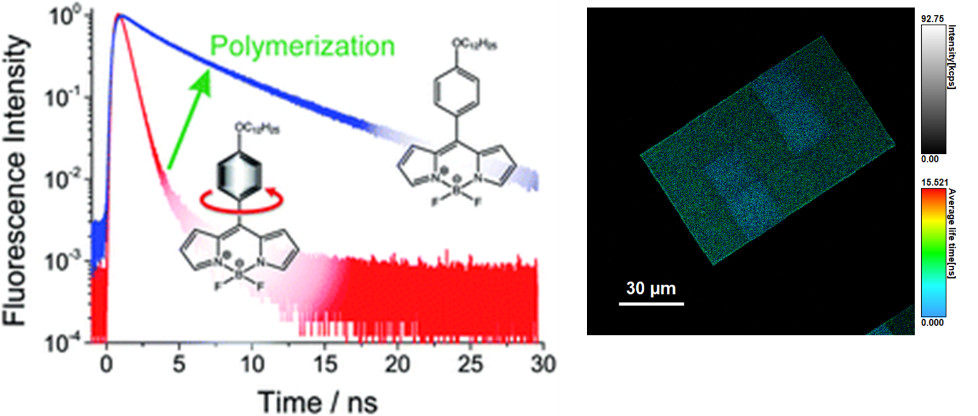

This fundamental activity is aimed at investigating the photophysical and photochemical properties of the photoresists and/or of the structured (photo)materials. Our group explores physical-chemical mechanisms that can link, arrange and assemble building blocks from the molecular level up to the microscale. In particular, the role of nanophotochemistry in optimizing 3D photostructuring (printing speed, resolution, etc.) is being investigated. Moreover, we investigate the interaction between different molecules and nanoscopic materials in complex hybrid nanostructures and the emergence of complex behaviour, using analytical chemical techniques and advanced spectroscopy and microscopy techniques.

Our experimental labs feature a wide range of chemical and optical characterization techniques such as Real-time FTIR spectroscopy, UV-Visible absorption spectroscopy, fluorescence spectroscopy, single particle microscopies and spectroscopies techniques (fluorescence steady state and time-resolved microspectroscopies, polarized dark field microspectroscopy…). Moreover, we have developed customized equipment for 3D micro-printing with multi-wavelengths and multi-materials capabilities, or with in situ diagnostic / visualization of the photopolymerization reaction.

A fluorescent molecular rotor has been successfully exploited as a viscosity probe to reveal heterogeneity in multi-material microstructures made by two-photon polymerization. These results open the door to probe the 4D character of active 3D microstructures.

Investigation of two-photon polymerized microstructures using fluorescence lifetime measurements, X. Wu, M. Belqat, B. Leuschel, G. Noirbent, F. Dumur, K. Mougin and A. Spangenberg, Polymer Chemistry 2022, 13, 2902 DOI : 10.1039/D1PY01728D

Functional materials for multi-scale 3D & 4D printing : from their synthesis to their integration

Original functional materials compatible with light-based additive manufacturing processes are developed to obtained multifunctional and/or programmable 3D/4D (micro-)structures. The photoresists cover a wide range of wavelengths from UV to Near-Infrared. A large class of materials are proposed (living polymer, degradable polymer, liquid crystal elastomer, hydrogel, hybrid materials, glass, carbon…) to meet a variety of requirements in optics, photonics, soft robotic, non-invasive surgery, (photo-) catalysis…

Based on macro-photoiniferter induced photo-mediated RAFT polymerization, 3D microstructures with high resolution are fabricated by 3D direct laser writing. Due to the fidelity of the RAFT agent, “living” surfaces can be modified repeatedly using normal or stimuli-sensitive materials. Compared to traditional 3D printing, this strategy provides a simple method to customize microstructures and paves the way to multi-materials and 4D printing.

Advanced Functional Materials 2022, 32, 2109446 DOI : 10.1002/adfm.202109446

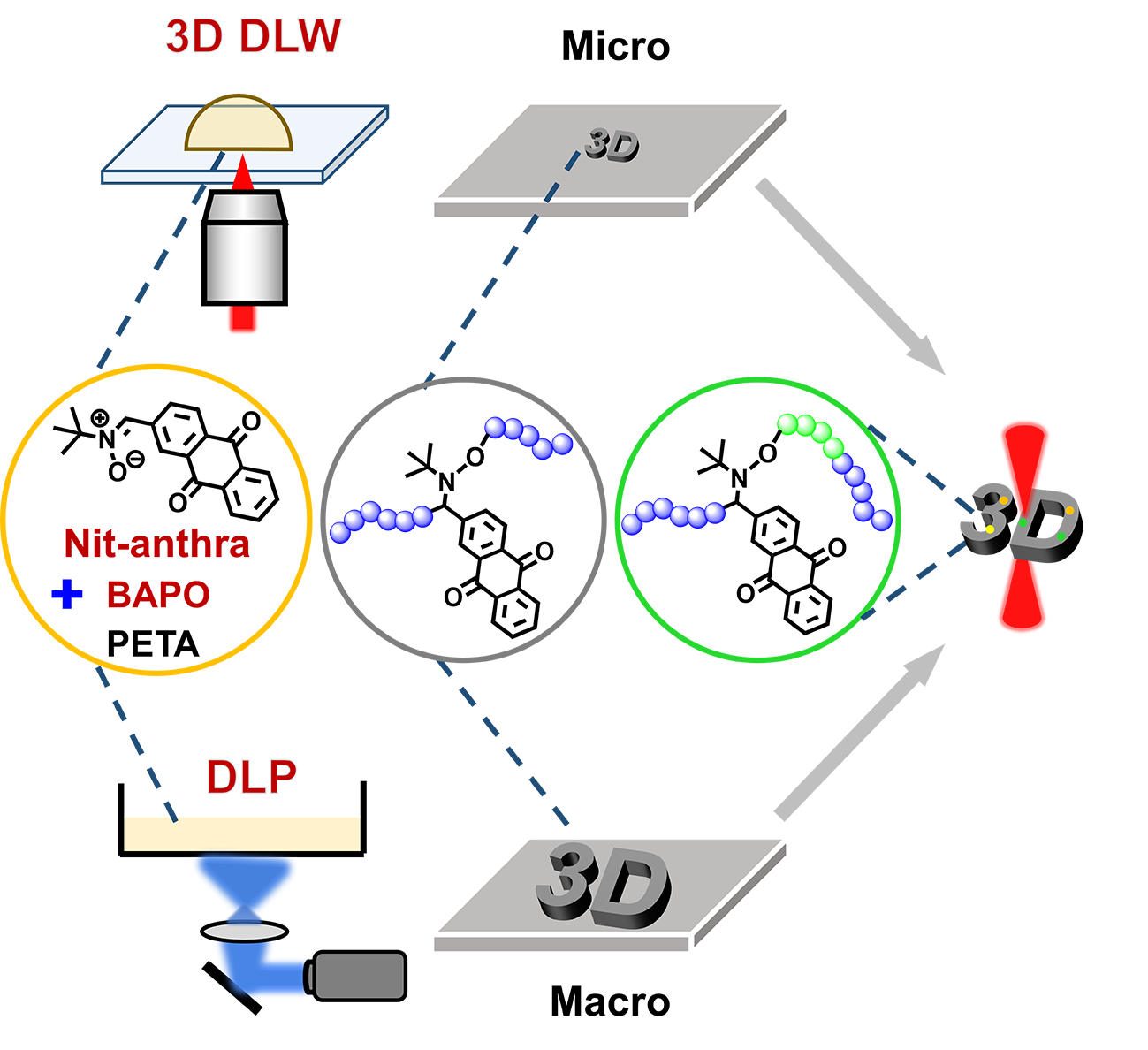

A new strategy – In-Situ NMP2 – is developed in 3D printing. Based on a novel photoresist containing a nitrone and a commercial photoinitiator, it can be facilely adapted to 3D DLW and DLP, and facilitates precise post-surface modification attributing to the in-situ formation of alkoxyamines during printing. This strategy bridges micro- and macro-3D printing and fuels the development of “living” printing.

Advanced Functional Materials 2024, 34, 2312211 DOI : 10.1002/adfm.202312211

Publications

Surface Modification of 3D-Printed Micro- and Macro-Structures via In Situ Nitroxide-Mediated Radical Photopolymerization,

X. Wu, B. Leuschel, N. Hoai Nam, Y. Guillaneuf, D. Gigmes, J-L. Clément, A. Spangenberg,

Advanced Functional Materials 2024, 34, 2312211 DOI : 10.1002/adfm.202312211

Customizable and Reconfigurable Surface Properties of Printed Micro-objects by 3D Direct Laser Writing via Nitroxide Mediated Photopolymerization,

M. Belqat, X. Wu, J. Morris, K. Mougin, T. Petithory, L. Pieuchot, Y. Guillaneuf, D. Gigmes, J-L. Clément, A. Spangenberg,

Advanced Functional Materials 2023, 33, 2211971 DOI : 10.1002/adfm.202211971

Investigation of two-photon polymerized microstructures using fluorescence lifetime measurements,

X. Wu, M. Belqat, B. Leuschel, G. Noirbent, F. Dumur, K. Mougin and A. Spangenberg,

Polymer Chemistry 2022, 13, 2902 DOI : 10.1039/D1PY01728D

On-demand Editing of Surface Properties of Microstructures Made By 3D Direct Laser Writing via Photo-mediated RAFT polymerization

X. Wu, B. Gross, B. Leuschel, K. Mougin, S. Dominici, S. Gree, V. Tkachenko, B. Cabannes-Boué, A. Chemtob, J. Poly, A. Spangenberg,

Advanced Functional Materials 2022, 32, 2109446

Tuning nanomechanical properties of microstructures by 3D direct laser writing,

M. Belqat, X. Wu, L. P. Chia Gomez, J-P. Malval, S. Dominici, B. Leuschel, A. Spangenberg, K. Mougin,

Additive Manufacturing 2021, 47, 102232 DOI : 10.1016/j.addma.2021.102232

Direct Laser Writing of Crystallized TiO2 and TiO2/Carbon Microstructures with Tunable Conductive Properties,

S.-Y. Yu ; G. Schrodj ; K. Mougin ; J. Dentzer ; J.-P. Malval ; H.-W. Zan ; O. Soppera ; and A. Spangenberg,

Advanced Materials 2018, 30, e1805093 DOI : 10.1002/adma.201805093

Rapid Prototyping of Chemical Microsensors Based on Molecularly Imprinted Polymers Synthesized by Two-Photon Stereolithography,

L. P. Chia Gomez, A. Spangenberg, X.-A. Ton, Y. Fuchs, F. Bokeloh, J-P. Malval, B. Tse Sum Bui, D. Thuau, C. Ayela, K. Haupt, O. Soppera,

Advanced Materials 2016, 28, 5931-5937, DOI : 10.1002/adma.201600218