Material and Energy Recovery from Bio-Based Products : Development of Chars

M. Jeguirim, M. Zbair

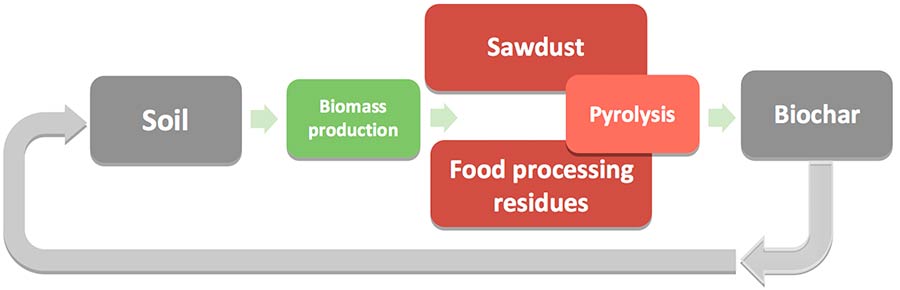

The development of renewable energies has become a major challenge to address the scarcity of fossil resources and the increase in greenhouse gas emissions. Among the strategies being considered, the thermochemical conversion of bio-based materials can combine both energy production and carbon sequestration. In particular, pyrolysis has the advantage of producing two fractions : liquid and gaseous, which can be used as biofuel, and a solid fraction called char, which can be recovered through various processes. Thus, char can be used directly for soil improvement, gasified under water vapor and/or CO2 for the production of syngas, or transformed into an adsorbent for the removal of pollutants in the gaseous and aqueous phases.

A strategy for the recovery of aqueous effluents from the agricultural-food industry has been developed. These effluents, rich in organic and mineral matter, are impregnated with bio-sourced materials. The resulting mixture is then dried for water recovery and pyrolyzed to produce bio-oils and biochar. The latter, rich in nutrients such as potassium (K), phosphorus (P), and nitrogen (N), is used as a biofertilizer for soil amendment.

Reprinted with permission from [The two‐dimensional pore and polarization transport model to describe mixtures separation by nanofiltration: Model validation, S. Déon, P. Dutournié, L. Limousy, P. Bourseau, AIChE Journal 2011, 57, (4), 985–995 DOI: 10.1002/aic.12330 ]. Jun 16, 2010 , John Wiley and Sons, Copyright © 2010 American Institute of Chemical Engineers (AIChE)

More recently, scale-up of the process was investigated through the acquisition of a continuous semi-industrial pyrolyzer capable of converting 10 kg/h of biomass into biochar. The pyrolyzer is fully instrumented and allows for varying residence time, temperature, and gas flow rate to produce biochars with different physicochemical and morphological properties. The process conditions in the three pyrolyzers available to the TRM2P research group (laboratory scale, batch medium-scale, and continuous semi-industrial scale) are correlated with the biochar characteristics to identify and predict the pyrolysis conditions required to produce final materials with targeted characteristics.

Publications

Optimization of hybrid treatment of olive mill wastewaters through impregnation onto raw cypress sawdust and electrocoagulation, M. Bargaoui, S. Jellali, A. A. Azzaz, M. Jeguirim, H. Akrout,, Environmental Science and Pollution Research 2021 28, 24470 DOI 10.1007/s11356-020-08907-w

Production of a biofertilizer from exhausted grape marc waste : agronomic and environmental impact on plant growth, . El-Bassi, A. Ibn Ferjani, M. Jeguirim, S. Bennici, S. Jellali, H. Akrout, N. Thevenin, L. Ruidavets, A. Muller, L. Limousy, Biomass Conversion and Biorefinery, 2020 DOI 10.1007/s13399-020-00991-9L

Biomass derived chars for energy applications B. Khiari, M. Jeguirim, L. Limousy, S. Bennici , Renewable & Sustainable Energy Reviews 2019, 108, 253 DOI 10.1016/j.rser.2019.03.057

The use of exhausted grape marc to produce biofuels and biofertilizers : Effect of pyrolysis temperatures on biochars properties, A. Ibn Ferjani, M. Jeguirim ; S. Jellali ; L. Limousy ; C. Courson ; H. Akrout ; N. Thevenin ; L. Ruidavets ; A. Muller ; S. Bennici, , Renewable & Sustainable Energy Reviews 2019, 107425 DOI 10.1016/j.rser.2019.03.034